Versions and designs

- The static Elektra testing panels feature robust steel plate housing powder coated in RAL 7035/5007.

- The line for the mains connection can be fed in from above or below.

- The mobile testing devices are built into a rigid plastic case (PGTL...).

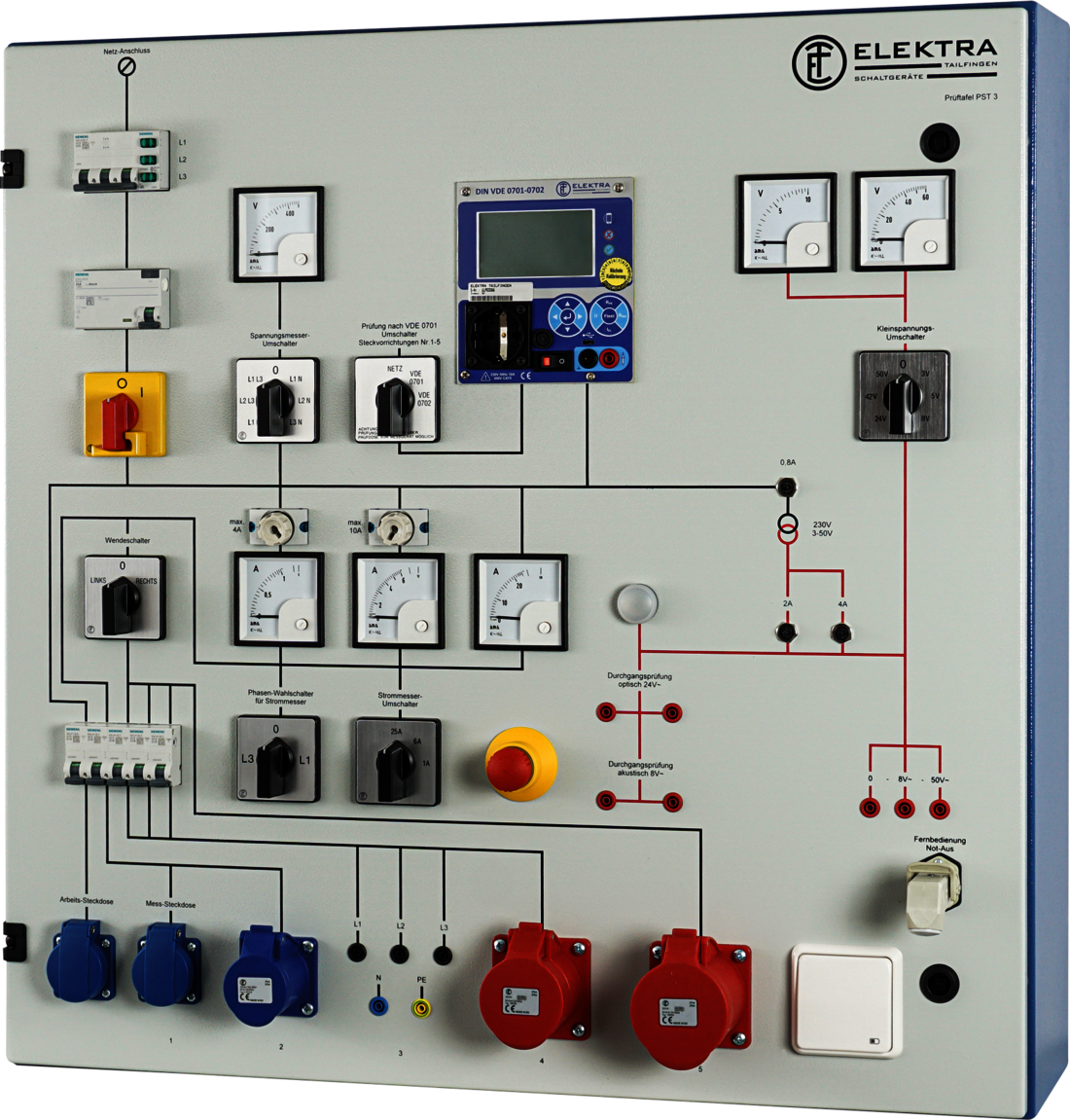

- The fronts of all testing panels feature a mimic diagram serving as an operator guide.

- All testing panels (except PGTL...) are equipped with a lockable main switch with low-voltage triggering, a residual current circuit breaker, 30 mA trip current and an emergency-off button.

- A connection socket for an external emergency-off button is additionally fitted into the static testing panels.

- All static testing panels can optionally be supplied with or without device testers.

- Our device tester features the residual current measurement process for measuring earthing conductor and/or contact current.

Elektra testing panels are supplied in the following designs:

- In steel plate switching cabinet housing as a static testing panel

- In duct construction form as the optimum solution on glazed walls or for free-standing test stations

- In suitcase design as portable test equipment for mobile use on site

Standards and regulations

Elektra testing panels conform to

- the Federal Installation Committee's 'Guidelines for Electrical Installation Operations' Workshop Equipment'.

- facilitate the testing of electrical resources in line with the requirements of

- DIN EN 50678 (VDE 0701) 'Maintenance, Modification and Testing of Electrical Resources'

- DIN EN 50699 (VDE 0702) 'Repeat Testing of Electrical Equipment'

- DGUV Regulation 3 (Electrical Plant and Equipment, former number BGV A3)

- are suited by virtue of their safety features to the setting up of a test station as per DIN EN 50109 (VDE 0104).

- facilitate in addition to the testing of protective measures quick and reliable testing of all key equipment functions.

OVERVIEW OF TESTING AND MEASURING EQUIPMENT

| Type | PST 1 | PST 2 | PST 3 | PST 4 | PST 5 | PST 6 | PST 7 | PSTD 3 | PSTD 4 | PSTD 5 | PSTK 3 | PTGL 1 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Data sheets | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 |

| Rated current | 25 A | 25 A | 25 A | 50 A | 25 A | 25 A | 25 A | 25 A | 50 A | 25 A | 25 A | |

SAFETY INSPECTION OF: | ||||||||||||

| AC consumers | x | x | x | x | x | x | x | x | x | x | x | x |

| Three-phase consumers | x | x | x | x | x | x | x | x | x | x | x | |

TEST CONNECTIONS: | ||||||||||||

| 16A 3p 230 V earthing contact | x | x | x | x | x | x | x | x | x | x | x | x |

| CEE 16A 3p 230V | x | x | x | x | x | x | x | x | x | x | x | x |

| CEE 16A 5p 400V | x | x | x | x | x | x | x | x | x | x | x | x |

| CEE 32A 5p 400V | x | x | x | x | x | x | x | x | x | x | x | x |

| CEE 63A 5p 400V | x | x | x | |||||||||

DISPLAY OR MEASUREMENTS: | ||||||||||||

| Multi-function meter unit | x | x | x | |||||||||

| Engine test | x | x | x | x | ||||||||

| Extension cable testing | x | |||||||||||